|

Strictly-Selected Raw MaterialsRaw materials inspection is a vital step in our process. We only adopt premium materials to manufacture high-quality machines. We guarantee a long service life and great performance by cooperating with famous brands and purchasing:

|

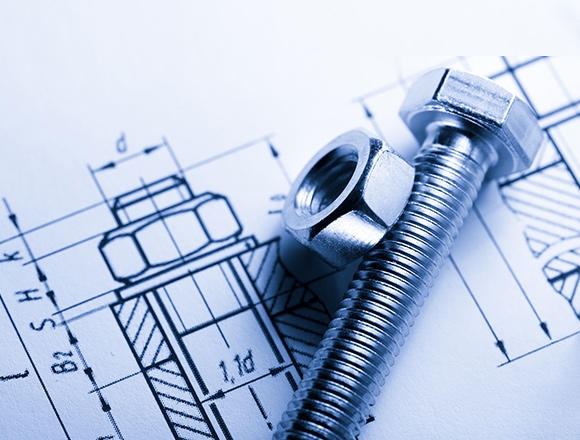

Professional Engineering DesignRationality of the engineering design makes sure the final machine performance. By utilizing state-of-the-art CAD software and the rich engineering experience, we efficiently create an accuracy design to meet your needs of specific products, packaging size, and materials. |

|

|

Skillful Parts ProcessingThe company has over 100 nationally cutting-edge cold-forged machines, wire-drawing machines and threading forming machines as well as perfect equipments for inspection and testing.

|

Advanced equipment/strong powerExcellent equipments quarantee the quality of products and automatic production, scientific workflow design, exquisite process level. first-class production streamline and orderly site management have provided reliable software and hardware quaranty for the further improvement of the product quality. Xinglong strongly believes that only by means of a constantly progressing technique and an advanced science & technological platform, can high-quality products be created for its customers and can the market favor its products and finally winning the respects from its customers. |

|

|

Strict Final TestWe will adjust the details to eliminate possible errors and safety risks before delivery by testing:

|